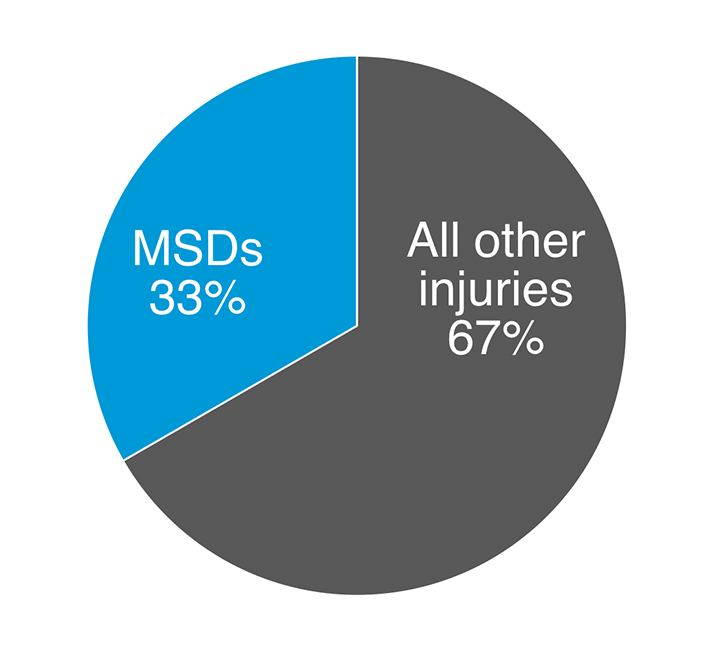

Musculoskeletal Disorders (MSDs) are the number one workplace injury in Canada. They account for the most lost-time injury claims and the most lost-time workdays. In 2017, MSDs cost Ontario employers $72 million in claim related expenses and resulted in 462,000 lost days.1

MSDs are often painful and in severe cases, can lead to a permanent disability. They are also preventable. One study concluded that the average annual ROI was 378%. In this article, we’ll help you understand what MSDs are, what causes them, and how to prevent MSDs so you can reduce the costs associated with them.

What are MSDs?

MSDs are injuries to the soft tissues and the nervous system that develop gradually over weeks, months, or years. They are commonly referenced as repetitive strain injury, overuse injury, cumulative trauma disorder, or strains/sprains.

Common musculoskeletal disorders include:

- Carpal Tunnel Syndrome

- DeQuervain’s Syndrome

- Lateral Epicondylitis (Tennis Elbow)

- Hand Arm Vibration Syndrome

- Low back pain

- Tendinitis

- Thoracic Outlet Syndrome

- Trigger Finger

What causes MSDs?

MSDs generally develop over time and are typically the result of many different factors. A worker’s risk of developing an MSD is affected by their:

- age

- lifestyle

- family history

- occupation

There are several work-related risk factors that can contribute to the development of an MSD.

Primary Risk Factors

High Force – Examples of force include the force exerted on a box during lifting or the grip force to hold a hand tool. Overexertion occurs when the force required exceeds the tolerance of the body’s tissues. The greater the force required, the greater the risk of injury.

Awkward or Static Postures – Awkward or static postures place excessive weight on joints. They overload the muscles and tendons around the affected joint. Bending over or holding a phone between your neck and shoulder are awkward postures. Holding any posture (including awkward postures) for a prolonged period of time can also contribute to the development of an MSD.

High Repetition – Repetition is the number of times a task or similar motion is performed per minute, hour, shift, or day. Highly repetitive tasks can cause muscle fatigue, damage to tissues and, eventually, pain. High repetition can affect office workers who perform a lot of work using their mouse.

Secondary risk factors include vibration, contact stress, and temperature. They may also contribute to the acceleration of an MSD, especially when combined with any primary risk factors.

How can you prevent MSDs at your workplace?

Preventing musculoskeletal disorders is less costly than managing them after they happen. MSDs can be prevented using the RACE (recognizing, Assessing, Controlling, Evaluating) model that we recommend using to manage workplace hazards.

# 1 Recognize and Assess Hazards

Set up a process for recognizing jobs and tasks with MSD hazards. If you don’t have a qualified ergonomics professional in your organization, you should work with a health and safety partner to perform the initial assessment.

In the process, the assessor will document the jobs and tasks, observe workers performing regular activities, and get input from workers either through conversations or a survey. Getting input from the workers who perform the tasks is crucial to getting an accurate assessment of the hazards. Workers will have a better understanding of how tasks are actually performed, and therefore what hazards exist.

On an ongoing basis, your joint health and safety committee or representatives should include MSD hazard identification and communication in their routine inspections. Your ergonomics partner can teach them what to look for and what information to communicate. You can also use our General MSD Hazard Identification Tool to remind you of what to look for during your inspections.

Download the MSD Hazard Identification Tool

# 2 Develop a Program to Eliminate or Control MSD Hazards

Once you have identified and assessed the MSD hazards that exist in your workplace, you need to come up with a plan to control them. If you cannot eliminate them, you will need to rely on other control methods. Exactly how you will control the MSD hazards will vary depending on the workplace, tasks, and equipment.

How Other Organizations Control MSD Hazards

Here are a few ways organizations have controlled MSD risks in their workplaces:

Machine redesign – in a food manufacturing facility, workers had to bend over to inspect their products on an assembly line. To prevent this awkward and static posture from leading to back strain, the employer raised the conveyor belt. Workers no longer had to bend to inspect the products.

Work practice – Washington State implemented legislation that mandated safe patient handling practices and lift equipment in hospitals. Several studies show that lift equipment and safe patient handling prevent MSDs.

Equipment – cashiers at a grocery store complained of sore feet and backs as a result of standing on the concrete floor all day. The employer provided anti-fatigue mats to help reduce the impact of standing. Other examples of equipment designed to prevent MSDs include anti-vibration gloves, telephone headsets, and kneepads.

Training – a large call centre wanted to reduce incidences of neck and wrist pain. They provided online ergonomics training to all of their workers. This training educated agents on the importance of changing positions, adjusting their workstation to suit their body, and optimal posture.

There are usually multiple ways to control for the same hazard. Ensure that workers are involved in every step of the process, including selecting the appropriate solution. You should also plan a test period to trial your new control. Sometimes implementing new equipment or practices can inadvertently introduce a new hazard. For example, introducing anti-fatigue mats could create a tripping hazard if the mats are not chosen and installed optimally.

Controls are Part of a Holistic MSD Prevention Program

Your new controls should be part of a holistic MSD Prevention Program. The program should also include:

Written policies and procedures – to communicate the employer’s commitment to its workers’ health and safety, as well as outlining responsibilities of the employer, supervisors, and workers in preventing MSDs.

Ongoing processes to recognize and control hazards – as mentioned above, your joint health and safety committee should include MSD prevention in their regular inspections and meetings

Education and training – Workers should be trained on how to recognize MSD risk factors, perform work safely, properly inspect and maintain equipment, and report injuries.

#3 Evaluate the Controls and Program

Once you have implemented new controls, you should evaluate the impact they have had on reducing MSD hazards. You can evaluate controls using injury reports, observations of procedures, and worker surveys. Health and safety, including MSD prevention, is an ongoing process. You should expect to make continuous improvements to your MSD Prevention Program as your workplace evolves.

Preventing MSDs requires a proactive approach. But, it can generate huge returns by reducing costs associated with injuries, improving productivity, and increasing employee retention. If you need help developing your MSD Prevention Program, we can help.

Prevent MSDs at Your Workplace

We’ve helped thousands of organizations improve the safety of their workplaces.

MSD Prevention Program Audit

Prevent injuries! We visit your workplace to help you launch or improve the processes you have in place to prevent MSDs.

Ergonimics Risk Assessment

We’ll review a specific area to assess force, posture, and repetition and provide ergonomic solutions to reduce risk while ensuring productivity.

Download the MSD Hazard Identification Tool

Prevent injuries before they happen. Ensure your JHSC is incorporating MSD prevention in their regular workplace inspections by using the MSD Hazard Identification Tool.

Sources 1Ministry of Labour Industrial Sector Compliance Plan